We have several methods to communicate our PC with the Delta PLC’s, and many users don’t know some of them.

On the other side, every time is more difficult to found RS232 serial ports in the computers, and the USB to RS232 converters are not as much trustable as they must, because of that I would like to list our alternatives to that problem:

Direct communication PC to PLC:

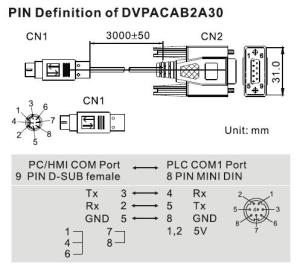

1. PC RS232 port to PLC RS232 port using the wiring DVPACAB2A30

2. PC USB port to PLC RS485 port using the device IFD6500 (Delta USB-RS485 converter).

3. PC Ethernet port to PLC DVPEN01-SL module (need compatibility with high speed bus)

Communication PC to PLC trough Delta HMI (Direct Link):

The direct link capability in Delta HMI is used to communicate with the PLC and HMI with one only wire. Furthermore this capability have been improved lately and now is possible monitor both of them at the same time using only one wire. (direct Link function updated)

1. Direct Link function trough Standard USB wire (WPLSoft and ISPSoft)

2. Direct Link function trough Ethernet (WPLSoft and ISPSoft)

Exactly the same feature is available with the new DOP-B HMI’s with Ethernet embedded, really helpful for remote support.

3. Direct Link function trough USB host (WPLSoft only).

All systems are Win XP / Win 7 compatibles, so now there’s no reason to do not communicate with Delta PLC.