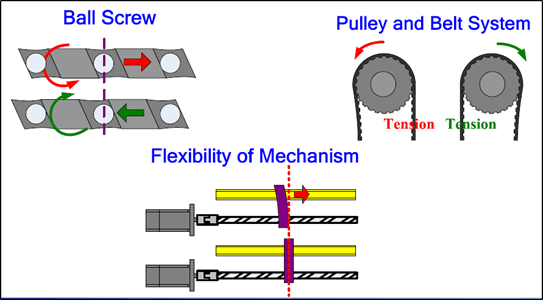

For high flexibility mechanisms that need precise positioning at a specific component, the full-closed loop control function is an excellent option. Moreover, for certain purposes, such as linear scale we utilize a second encoder for a linear scale too.

Examples of high flexibility systems can be belt/pulley-driven system, ball screw system, and some gear systems with backlash.

Using the Full-Closed loop control, any backlash or pitch error can be compensated.

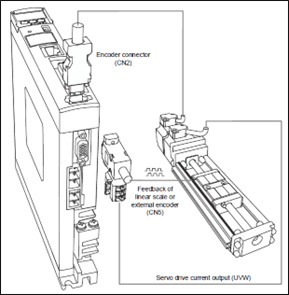

Basically, Full-Closed Loop is using 2 encoders within the control loop to operate the servo system. The main encoder and the auxiliary encoder. The auxiliary encoder returns the actual position of the machine end to the servo drive in the full-closed loop system. The main encoder returns attached directly to the motor and gives the actual motor position.